Many organizations order multiple items from suppliers on a repetitive schedule—weekly, bi-weekly, monthly and so on. These same organizations maintain Reorder Points (ROPs) by item which triggers “when” to place orders. These ROPs and the repetitive reordering are incompatible; they work at odds with each other. The way to correct this incompatibility is to place “Balanced Orders”.

Repetitive ordering and ROPs are at odds with respect to each other for the following reason: Items should be ordered when their on-hand inventory position reaches their ROP. But only one item of a given supplier will reach its ROP first; a time at which none of the other items will have reached their respective ROPs. Therefore, if the reorder is made-up of multiple items of that supply, all but one will be reordered early, crating more inventory of those items than if they were ordered at their ROPs.

This happens merely because of the randomness of demand. Some item must be first to reach its ROP and there’s no reason the others will reach their ROPs at that same time. Even if you “planned” to have all items reach their Reorder points at the same time, it’s virtually certain they wouldn’t.

Repetitive multi-item reorders to a supplier are regularly placed based on procurement economics—order a minimum amount, an EOQ, a truckload, a pallet, a case and so on, usually driven by transportation economics. This approach dominates the distributor industry, for example. So, orders driven by the first item to reach its ROP typically are augmented with other items from that supplier that will make-up a procurement-economical order. This invariably requires other items be added to the one that triggered the reorder—that reached it ROP first.

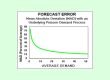

Making an order of multiple items gives the inventory planner the opportunity to rebalance the inventory to minimize the early order inventory, to cause all the items to reach their ROPs at the same time, next time. This is a Balanced Order; one that, when it comes in, places the inventory in a position that plans for each item to reach its Reorder point at the same time going forward. That this does not actually occur, due to the randomness of demand, is no reason not to do it.

Placing Balanced Orders is the way to eliminate surplus inventory created by the manifest randomness of demand.