Dynamic Slotting with “Expected Time To Pick”

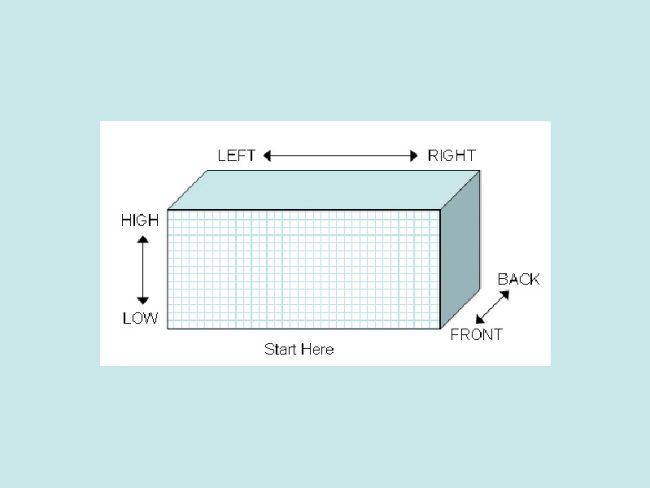

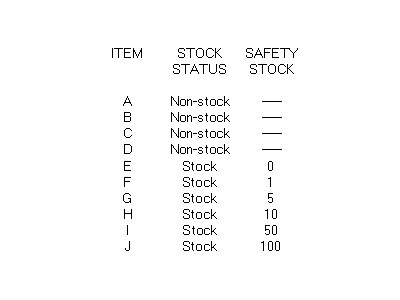

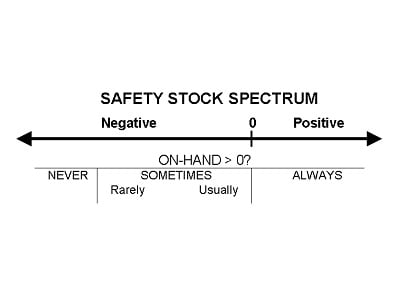

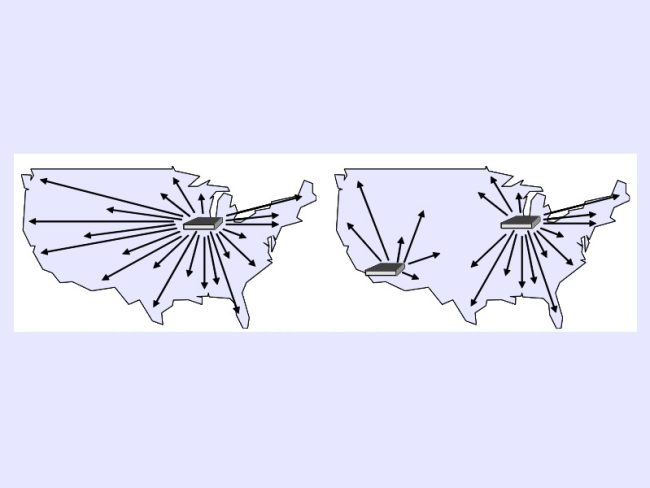

DYNAMIC SLOTTING WITH “EXPECTED TIME TO PICK Don’t Zone Your Warehouse, ETP it By Terry Harris, Managing Partner, Chicago Consulting Zone Approach Traditional slotting techniques use a Zone structure. The warehouse is divided into a group of Zones, typically a handful of them. Then each position in a particular Zone is viewed the same as…