Warehouse Operations – How a warehouse is designed and the processes it employees determines its performance – the Cost it takes to operate and the Service it provides customers. Getting the design right at the outset and keeping it optimal as your business evolves is key.

Warehouses receive, store and pick material. Normally receiving is done in larger quantities than picking making it the more productive of the two. Accordingly picking is the activity around which warehouse processes are initially designed.

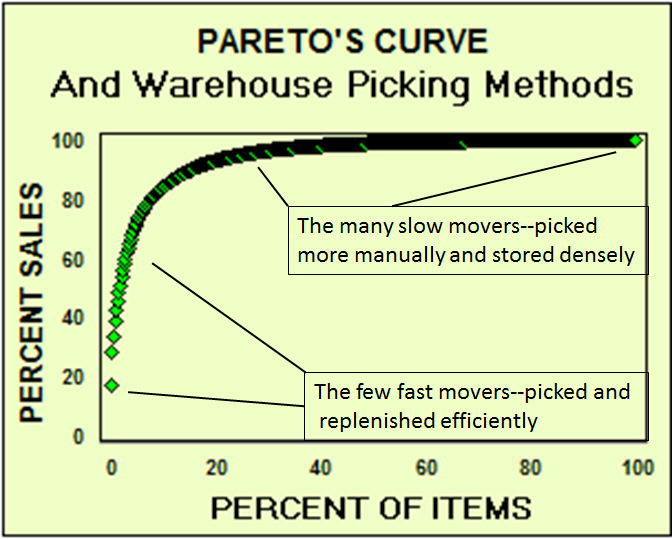

Most businesses operate within the law–Pareto’s Law that is – the 80-20 rule. This pattern helps design warehouse operations. With it you can make picking methods span an automation spectrum–from highly automated down to completely manual. The same principal applies to storage methods and slotting as well.

Businesses with strong Pareto’s Curves may be missing an opportunity if their picking methods don’t fit their curves.